Protein-specific packaging for a growing market

Protein is the rage, and consumers love meat. Beef, pork, and poultry remain strong center-of-plate entrees both at home and away. Our packaging solutions focus on key benefits like enhancing shelf appeal, reducing costs, improving line efficiencies, reducing leakage, and improved sustainability vs. other products.

Our meat & poultry packaging solutions include ClearShield® patchless bone-in technology, Envio® forming films, Nextrus® boneless vacuum shrink bags, and TuffTite® fresh or frozen poultry bags. And our Versaflex® in-line off-line bagging equipment ideal for providing “on demand” bagging of fresh, refrigerated boneless meat.

- Boneless Shrink Bags

- Bone-In Shrink Bags

- Poultry Shrink Bags

- Forming &

Non-Forming Films - Chub Films

- Versaflex® in-line off-line bagging equipment

The next generation of shrink bags, easy-to-use, tough-to-abuse.

- Durable, abrasive and puncture resistant films

- Exceptional moisture and oxygen barrier, proprietary sealant and extrusion technology

- High shrink performance, conforms tightly to product, minimizes tears and maintains vacuum tightness

- Proven machineability for equipment efficiency

- Food safety first, SQF Level 3 certified

- Nextrus®

Boneless Vacuum Shrink Bags

- Superior optics with glass-like clarity

- Excellent high gloss finish

- 2-sided, high-quality, 10 colour graphics

- Available in shrink bags or tubestock for Versaflex® in-line off-line bagging equipment

- Maraflex®

- Low temperature shrink (LTS)

- Complies with the standard FDA/USDA food additive requirements for direct food contact

Maximum impact and toughness that’s a cut above

- Proprietary co-extrusion patch free bag technology

- Durable, abrasive and puncture resistant films

- Exceptional moisture and oxygen barrier, proprietary sealant and extrusion technology

- Wide sealing range, seals through pleats & brine

- Proven machinability for equipment efficiency

- Food safety first, SQF Level 3 certified

- Clearshield®

- Crystal-clear, haze-free packaging

- Excellent high gloss finish

- Complies with the standard FDA/USDA food additive requirements for direct food contact

- Available in shrink bags and tubestock

- Thinner gauge alternatives for institutional or case-ready

Poultry bags that are tough AND beautiful for fresh & frozen poultry

- High shrink for package tightness

- Durable, abrasive and puncture resistant films

- Wide seal range for challenging whole bird applications

- Low stiffness for tight package after evacuation

- Food safety first, SQF Level 3 certified

- TuffTite® Poultry Shrink Bags

- Excellent high gloss finish and opacity

- High-end graphics with up to 10-colour, 2-sided printing for vibrancy and shelf appeal

- Available in clear, white, or cream colored bags

- Available in non-barrier for extended poultry shelf life

Best in class forming films for fresh and processed meats

- Outstanding seal integrity

- Durable, abrasive and puncture resistant films

- Precise gauge control for consistent roll profile (+/- 2%)

- Widest processing window for forming, sealing and tracking

- Food safety first, SQF Level 3 certified

- Envio® Films

Proprietary, first to world water quench forming films

- Superior optics with glass-like clarity

- Excellent high gloss finish

- Easy peel, peel reseal, hermetic, and lock-up seals

- Wide sealing range, seals through contamination

- High and low barrier options

Keeping it fresh

- Chub films for ground beef application

- Laminations that provide shelf life for refrigerated applications

- Exceptional moisture and oxygen barrier

- High speed films and structures for efficient processing

- SQF certified plants

- Chub films

- Excellent slip characteristics provide smoother packaging on high-speed equipment

- Exceptional oxygen barrier

- Puncture resistance to withstand abuse and clips

- Low stiffness for easy filling

- Produces consistent, superior seals throughout

- Wide operating window for sealing

- High elasticity prevents splitting upon filling

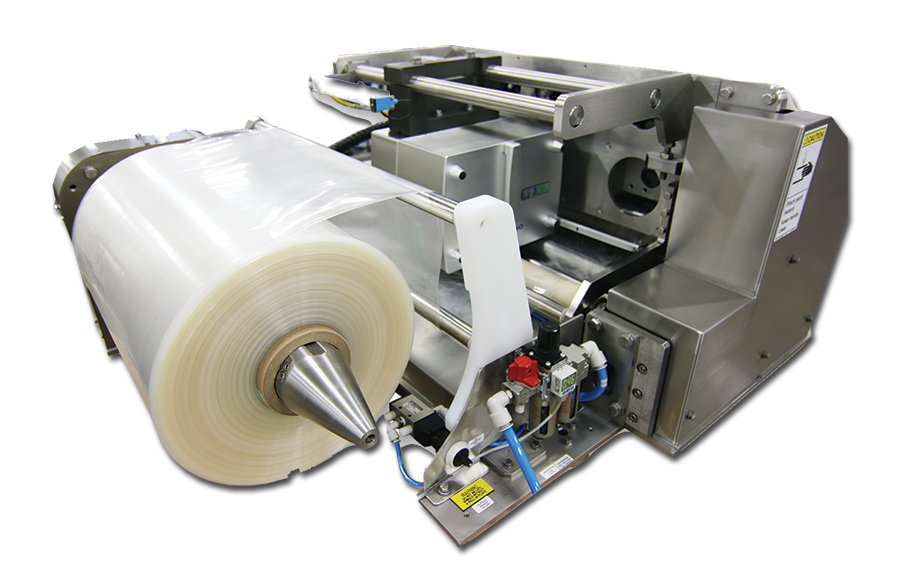

“On-Demand” in-line/off-line bagging equipment for fresh, refrigerated boneless meat

- Customized bag sizes on-line, on-demand

- Print on-line, date and time stamping, logos, USDA marks, lot tracing

- Simple and robust design

- Easy to maintain

- Works seamlessly with Clearshield® and Nextrus® tubestock

- Versaflex® in-line off-line bagging equipment

- Presents cost savings through reduced inventory

- Increased fulfillment speeds

- Improved traceability

- Eliminates product obsolescence