Extrusion Capabilities that Seal the Deal

Whether you need simple mono layer or more complex coextruded films, we have the answer.

The process begins with high quality resins that produce high-performance, high-quality sealant films for all our extruded films. And you get proficiency with film extrusion delivered by employees with 50+ years of experience and technical expertise.

We formulate most of our films for specific end-use applications in the food industry. Multi layers. Cast or blown. All you need to remember is TC Transcontinental Packaging.

Expertise & Technology

- Depth of expertise in resin blending, developing engineered films, and providing on-site support

- Maintaining a strong and growing asset base of state-of-the-art extrusion technologies

- Ongoing research & development to develop high performance films with improved attributes

- Proprietary film solutions that support the dairy, confectionary, protein, industrial and pet food markets

Cast Film Extrusion

- Cast polypropylene films

- Cast polyethylene films

- Durable nylon 6,6 cast films

- MDO films

- Biaxial oriented films

- Exceptional gauge and thickness control

- Wide range of widths

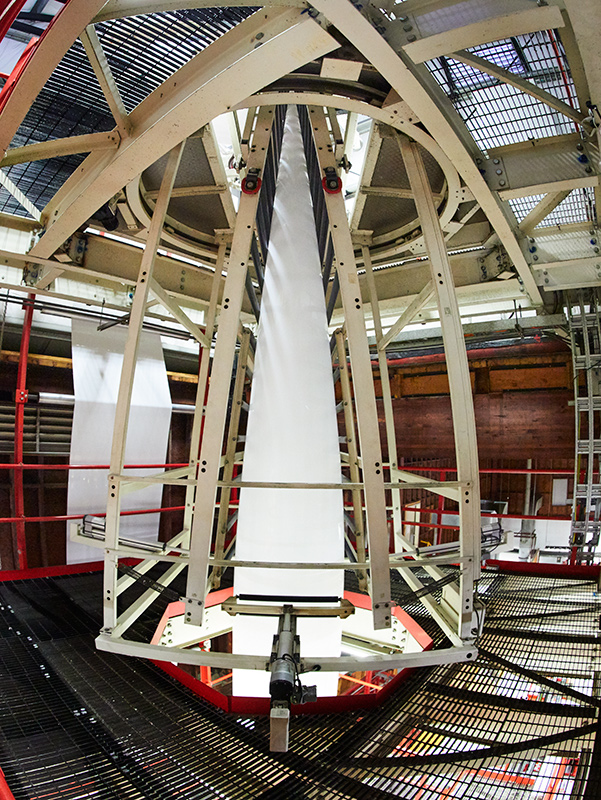

Blown Film Extrusion

- Significant, high-end blown extrusion capacity, multi-layer (up to 11) barrier films

- Full line of custom films that provide exceptional machinability, heat resistance, durability, sealability, and barrier

- Proprietary water-quenched films for extraordinary gloss and clarity

- EVOH barrier Film

- Forming films

- Vacuum shrink films

- FFS rollstock

- Collation shrink films

- Stretch hood films

- Oriented shrink films

- Biaxally orienting films

- Wide thickness range

- Innovative sealant technology through custom resin blends

Learn more about how you will benefit from our proprietary film technologies:

- Dartek® nylon cast film 6,6 gauge, for industrial uses

- Envio® forming films for cheese and meats

- Nextrus® shrink bags for meats and proteins

- ClearShield® for meats and proteins

- PolarFlex® for frozen foods

- Halo® EVOH encapsulated films for cheese