- Down gauging material thickness through improvement of material properties

- Partner with raw material suppliers, with an emphasis on resins and films to source more environmentally friendly and lower cost materials

- Educate and guide clients on alternate structures selections to achieve sustainability objectives

Your sustainable

packaging journey

What is a sustainable package?

The Sustainable Packaging Coalition (SPC) developed a definition of sustainable packaging which serves as a 'target vision' for companies.

— It is beneficial, safe & healthy for individuals & communities through all its life-cycle.

— It meets market criteria for performance and cost.

— It is sourced, manufactured, transported and recycled using renewable energy.

— It optimizes the use of renewable or recycled materials.

— It is manufactured using clean production technologies and best practices.

— It is made from materials that are healthy through the life-cycle.

— It is physically designed to optimize materials and energy.

— It is effectively recovered and utilized in biological and/or industrial closed loop cycles.

10 steps to creating a sustainable packaging

1

Choose a collaborative packaging partner that has experience and a deep understanding of developing sustainable flexible packaging.

2

Outline and define your sustainability goals, the product protection requirements, and your consumer’s needs.

3

Assess your packaging from a complete lifecycle perspective and consider having an LCA (Life Cycle Assessment) completed.

4

Work with your packaging partner to consider if lightweight and source reduction is viable for your package.

5

Consider end-of-life options such as compostable, recyclable or adding post consumer recycled (PCR) material to your package materials.

6

Build a strategy to manage your recycled, compostable, or PCR content costs.

7

Ensure your packaging graphic requirements will be compatible with your end-of-life scenario.

8

Consider 3rd party certification.

9

Ensure your package labeling is accurate and follows the required certification guidelines.

10

Utilize your graphic design on the front of your package to educate and engage your consumers about the sustainable attributes that differenciate your package.

Additional helpful information: www.findacomposter.com & https://how2recycle.info/sdo

40% of consumers say recyclable packaging impacts product choice!

64% of consumers believe that Food & Beverage Manufacturers are responsible for providing environmentally friendly options.

Source: Mintel Food Packaging Trends - U.S

Click on each section to see our approach.

- Develop packaging that has less waste generation and raw materials

- Create portion-controlled packaging that minimizes food waste

- Redesign to eliminate the need for excess packaging such as mother cartons

- Create high-barrier films to reduce food waste and extend shelf life

- Develop lighter packaging that reduces transportation weight

- Develop structures that have recyclable, bio-degradable, or compostable properties

- Incorporate PCR or PIR

Reduce the environmental impact of our operations by:

- Measuring air emissions

- Optimizing waste management

- Monitoring water use and wastewater discharge quality

- Reducing energy consumption

- Expanding the scope of reporting

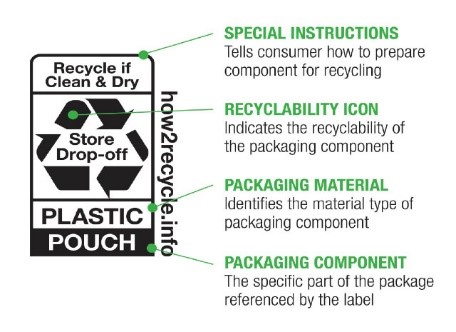

CORRECTLY LABELLING YOUR SUSTAINABLE PACKAGE

Choosing a partner to support you through your sustainability journey is vital in reaching your goals. When you choose TC Transcontinental Packaging, you gain a partner that has pioneered award-winning sustainable packaging solutions that are certifiable and commercialized.

We can assist you in ensuring that your package graphics clearly identify its end-of-life scenario.

Guidelines are continually changing and to ensure your package ends up in the correct stream you want to communicate it to the consumer in an easy-to-read and legible manner to facilitate the end-of-life process.

We’ve gained an extensive knowledge of the complexities and nuances of the entire process from design, ink choices, labelling guidance, and structure creation to help you in attaining the certifications you require.

RECYCLABLE PACKAGING LABELING

Unclear labeling, and inaccurate recyclability claims make proper recycling a challenge. The How2Recycle label, a project of the Sustainable Packaging Coalition, was created to provide consistency and transparency on-package recycling information to consumers in North America.

For more information, visit their website.

COMPOSTABLE PACKAGING LABELING

BPI is North America’s leading certifier of compostable products and packaging. BPI third party certification program ensures that products and packaging displaying the BPI logo have been independently tested and verified according to scientifically based standards.

For more information, visit their website.

Sustainable Packaging Terms & Definitions

Click on a word to view its definition.

Barrier

A material that is designed to prevent or significantly reduce the penetration of water, oils, water vapor or gases as desired. Barriers often serve to extend the shelf life of food products.

Bio-based plastics

Bio-based plastics are made from renewable resources instead of non-renewable petroleum-based resources. These renewable resources can include corn, potatoes, rice, soy, sugarcane, wheat, and vegetable oil.

Bioplastics

This category denotes polymers that are derived from existing biological — and therefore renewable — resources. The term, bioplastics, does not convey the percent of biological content. A hybrid structure comprised partly or even mostly of petroleum-based plastic can still be called a bioplastic.

Biodegradable

Biodegradable refers to the ability of materials to break down and return to nature. In order for packaging products or materials to qualify as biodegradable, they must completely break down and decompose into natural elements within a short time after disposal – typically a year or less. Not to be confused with compostable. Being biodegradable is just one the many factors a compostable package must meet.

Carbon footprint

This is the total amount of carbon dioxide an individual or other type of group/organization produces to maintain their lifestyle for a specified amount of time. Examples of factors that contribute to one’s carbon footprint include energy usage, transportation, and products used.

Carbon-neutral

Making no net release of carbon dioxide to the atmosphere, especially through offsetting emissions by planting trees.

Chemical recycling

Recycling process where polymer chains are reduced to constituent components through chemical processes. These components can be reconstituted into plastics, or alternatively used in plastics-to-fuel processes.

Circular economy

A circular economy is one that aims to move away from the consumption of finite resources by designing waste out of the system, it is based on three key principles: design out waste and pollution, keep products and materials in use, regenerate natural systems.

Closed-loop system

Closed-loop recycling indicates that a product can be recycled back into itself (as in bottle-to-bottle recycling), while open-loop recycling indicates that it is recycled into other types of products (e.g. bottle into fiber).

Compatibilizer additives

It allows resins that would not normally blend to bond in a way that creates enhanced performance when compared with either polymer individually. No ‘one-size-fits-all’ compatibilizer exists on the market today. For compatibilizers to work consistently, the recycle feed-stream itself has to be fairly consistent in resin composition.

Compostable

This term means that a product is capable of disintegrating into natural elements in a compost environment, leaving no toxicity in the soil.

Developed-to-be-recyclable

This term refers to packaging that is recyclable and has proven to be recyclable in practice and at scale. Whether or not it can be recycled in practice depends very much on the local recycling infrastructure.

Cradle to Grave

Is used in reference to a firm's perspective on the environmental impact created by their products or activities from the beginning of its life cycle to its end or disposal.

Downcycling

The process of converting materials and products into new materials of lesser quality or with limited reuse ability. In terms of CO2 emissions, it is just as environmentally friendly as recycling something back into itself.

Downgauging

Using less of certain materials (e.g., moving to thinner films) to reduce a product’s lifecycle impact and minimize costs.

End Market

Refers to the final product after recovery. The product which then goes back into consumer re-use.

Engineered fuel

Material is pressed into pellets or cubes to be combusted as fuel in industrial boilers or power generation plants. Engineered fuel is seen as an alternative to partially replace primary fuels such as coal or biomass.

Extended Producer Responsibility (EPR)

A policy approach under which producers are given a significant responsibility – financial and/or physical – for the treatment or disposal of post-consumer products.

Engineered landfill

A facility designed to sequester waste while minimizing environmental impacts from leakage to the environment including blown debris, groundwater contamination, and methane release.

Life-cycle assessment / Life cycle analysis (LCA)

LCA is a technique used to assess the environmental impacts associated with every stage of a product's life, from raw material extraction through to materials processing, manufacturing, distribution, use, repair and maintenance, and disposal or recycling.

Lightweighting

Reducing packaging weight to promote environmental sustainability and minimize costs.

Material recovery facility (MRF)

Specialized facilities that receive, separate and prepare recyclable materials. Upon sortation these materials are sold and sent onwards to processing facilities.

Mechanical recycling

A recycling process referring to operations that aim to recover plastics waste via mechanical processes (grinding, washing, separating, drying, re-granulating and compounding). In mechanical recycling polymers stay intact.

Multi-material flexible film

Regardless of the layer structure, a film made of multiple polymers, fiber, or metallic materials. Multi-material films are highly engineered to deliver a broad range of protective properties while requiring the minimal amount of material possible. While multi-material flexible films are extremely effective at protecting products, their multi-material nature can complicate efforts to recycle them.

Multi-layer flexible film

A flexible film constructed of two or more layers of film. Such films may be composed of multiple polymers or other materials, or may be composed of a single type of material.

Near-infrared (NIR) optical sorting

NIR is one type of optical sorting technology that enables plastic packaging to be separated by polymer type into different plastic recycling streams.

Organic

A word that describes things that are natural or related to nature. In common usage, organic is used to mean “healthful” or “close to nature.” It can also describe foods grown without artificial pesticides or fertilizers.

Post-consumer recycled (PCR) plastic

Materials that have served their purpose (have been used by the consumer) and subsequently been recycled to produce a new product. The use of post-consumer-recycled (PCR) content in packaging is the use of recycled content into the packaging where virgin material may have been the norm.

Recyclable

Packaging that meets accepted design standards for recyclability, i.e. packaging with the right attributes for successful collection, sorting, and recycling in the real world.

Recyclability

Ability of waste materials to be captured and separated from the waste stream for conversion into a new item for reused in some capacity. This is a quality that depends upon the composition of the packaging, the ability of the recycling infrastructure to collect, sort, and reprocess it, and the existence of strong end markets to use the recycled material in new products.

Recycling streams

Recycling streams refer to the categories that materials are sorted into to prepare for sale into the market. In terms of packaging, common streams are aluminum, paper, polyolefins (PO) for flexible plastics and PET for rigid plastics.

Resin identification code

A resin identification code specifies what type of plastic a package or product is made from, such as PET or polypropylene (PP). It does not imply whether the package is recyclable or not.

Responsibly sourced materials

Raw materials sourced from socially and environmentally responsible suppliers, as confirmed by certification schemes.

Single-stream recycling

A system in which all materials to be recycled are collected in one mixed container, instead of being pre-sorted. It tends to encourage more items to be put out for recycling but adds cost to the process and can impact the quality of the recycled materials.

Upcycling

The process of transforming by-products or waste materials, into new materials or products of better quality or for better environmental value.