vieVERTe®

PCR

Creating value for plastic waste

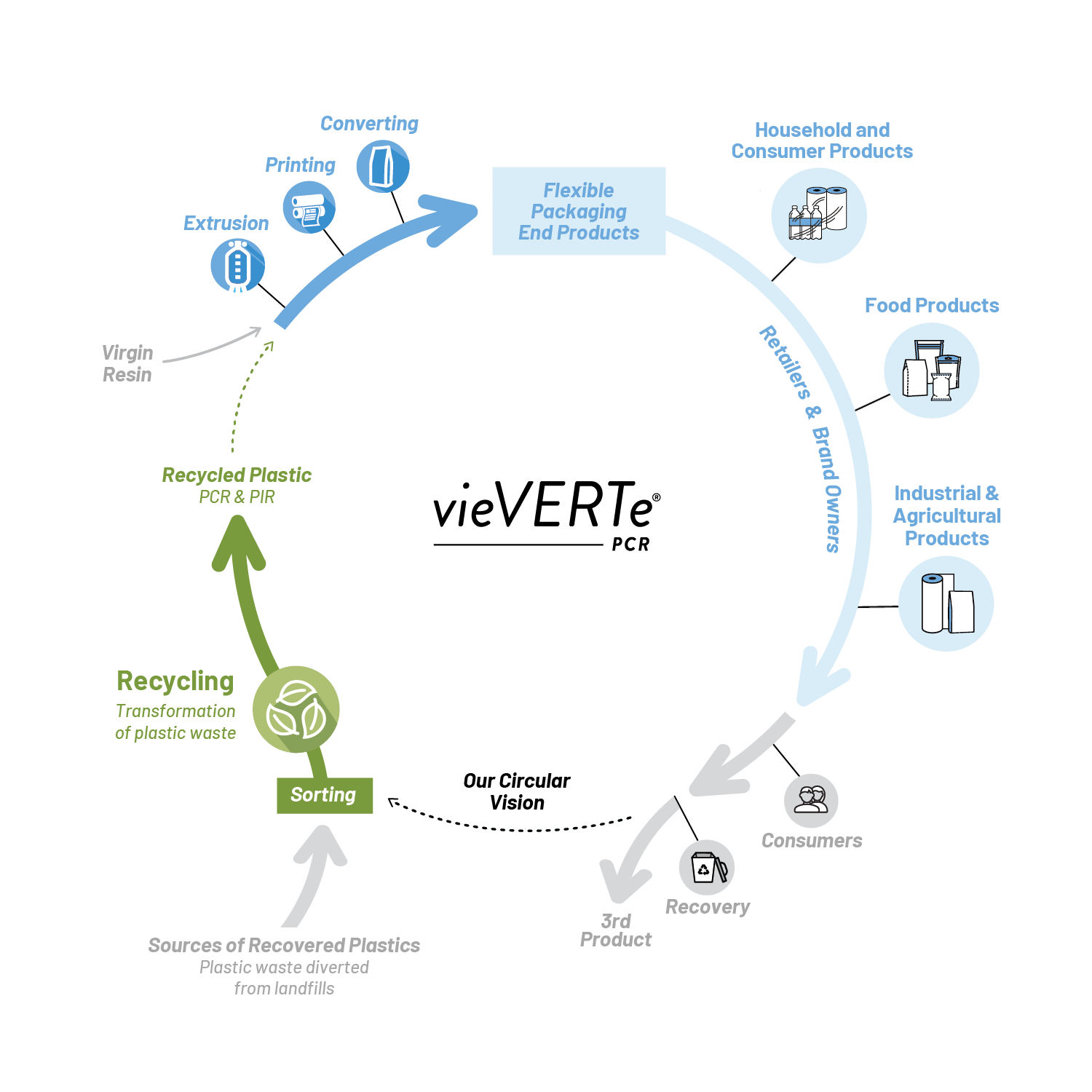

Packaging made with recycled plastic waste; we share the vision of a circular economy for plastic where plastic never becomes waste.

Our vieVERTe® PCR line of sustainable packaging products can contain up to 100% of recycled plastic waste depending on your sustainability objectives, applications, and industry. For both non-food and food contact products, and without sacrificing performance, strength, and durability. We are introducing films with similar performance to virgin plastic resin that can be recycled at store drop-off locations and have excellent mechanical properties and machinability. They also look great on the shelf and appeal to the consumer's desire for a cleaner environment.

Look for our packaging made with PCR: Beverage, cheese & dairy, home & personal care, snacks & dry food.

Compostable Bag

- Meets BPI certification for industrial composting with proprietary compostable sealants, adhesives, and coatings.

- Fits perfectly for closed-loop environments, with products used in locations where waste collection is controlled and have a partnering composting facility such as university, arenas, stadiums, national parks, airports, and foodservice.

- Delivers excellent machinability with engineered films to run on majority of existing FFS machinery.

- Looks great on shelves with matte and gloss finish options available.

Download our brochure to learn more about our vieVERTe® compostable offering.

APPLICATIONS: snacks, dry foods, coffee.

PCR Stand-Up Pouch

- Produced with up to 35% of post-consumer resin, reducing use of virgin plastic, creating value for plastic waste, and contributing to the circular economy for plastics.

- Made in all sizes and styles.

- Enhances consumer experience with convenience features such as resealable options.

- Maintains excellent brand image with superior optical properties, minimal gels or imperfections visible to the naked eye.

Download our brochure to learn more about our vieVERTe® PCR offering.

APPLICATIONS: snacks, dry foods, shredded cheese, and other food products with similar machine filling and high barrier requirements.

Recycle Ready Multilayer Stand-Up Pouch

- 100% multilayer pouch with barrier, pre-qualified for the How2Recycle® label, recyclable at existing in-store drop-off locations or curbside where available.

- Keeps product freshness and flavor with high and low barrier film options.

- Enhances shelf appeal and brand awareness with superior gloss and matte finishes.

- Monolayer options also available which offer high quality surface print with heat resistant coatings.

Download our brochure to learn more about our vieVERTe® recycle ready offering.

APPLICATIONS: bakery, snacks, dry foods, coffee, and tea.

PIR or PCR… what’s the difference?

Flexible packaging containing recycled content means the product was made from materials recovered or separated from the "waste stream" and re-used. A package can be classified as containing recycled material if it utilizes waste material that is post-industrial and/or post-consumer. There is a difference between these two materials but both are very valuable when considering a sustainable packaging solution.

Post-Consumer Resin (PCR)

is resin created from plastic waste that was used by the consumer for its intended purpose, has reached its end of use, and then tossed into a recycling bin. PCR can be material that is curbside collected, household single-stream recyclables, or recyclables that are collected through deposit collection locations.

Post Industrial Resin (PIR)

is resin created from plastic waste gathered from industrial/manufacturing production waste that did not meet its intended purpose and has been collected for recycling.

Ensuring stable and high-quality supply of recycled resins.

We collaborate with the industry and develop long-term partnerships with recyclers and businesses to incorporate HDPE and LDPE FDA-approved and non-FDA recycled resins into our packaging. In addition, to ensure the stable procurement of recycled resins and meet our 2025 sustainability commitments, we have integrated the recycling of plastics into our own production chain .

These activities allow us to:

- Have a better understanding of waste source;

- Increase sourcing for a more predictable quality, volume, consistency, and performance;

- Develop the purest PE with the required density, melt flow and other characteristics critical for your unique applications.

The LDPE post-commercial and post-consumer resin we produce has been tested and certified by the Association of Plastics Recyclers (APR), endorsed by SCS Global Services as 100% post-consumer recycled content. Also, our recyling facility based in Montréal, Québec, conforms to the SCS Recycling Program Standard for efficiently processing post-consumer waste material for landfill diversion and incorporate it as post-consumer recycled content.

Developing sustainable innovation

Our ASTRA Center is at the core of our operations to deliver on our 2025 commitment and be your sustainability partner. It is a fully integrated, state-of-the-art, research and development center and a turnkey solution for innovative packaging development within a packaging manufacturer.

The many tests, instruments, and technology available to our R&D team provide enhanced product development knowledge through the entire process of flexible plastic packaging design. We develop innovative films for sustainability, e-commerce, and more.